The development of synthetic fibres has always been a compromise: they are either strong or elastic – attaining both at the same time is considered a challenge. Researchers from the working group around Dr. Jonas Wolff at the University of Greifswald have discovered a special structure in a spider’s web that could be a solution to this industrial problem.

Net-casting spiders (Deinopidae), which live in tropical and subtropical regions, are particularly fascinating in this context. “They do not rely on a passive trap, but instead hold a sticky net between their front legs that they throw at their prey at lightning speed – this is an elastic feat of strength for the silk, which made us curious to find out what this material consists of,” explains Dr. Martín Ramírez, co-author of the study from the Buenos Aires Museum of Natural Science.

The material properties of the “curly” silk are decisive

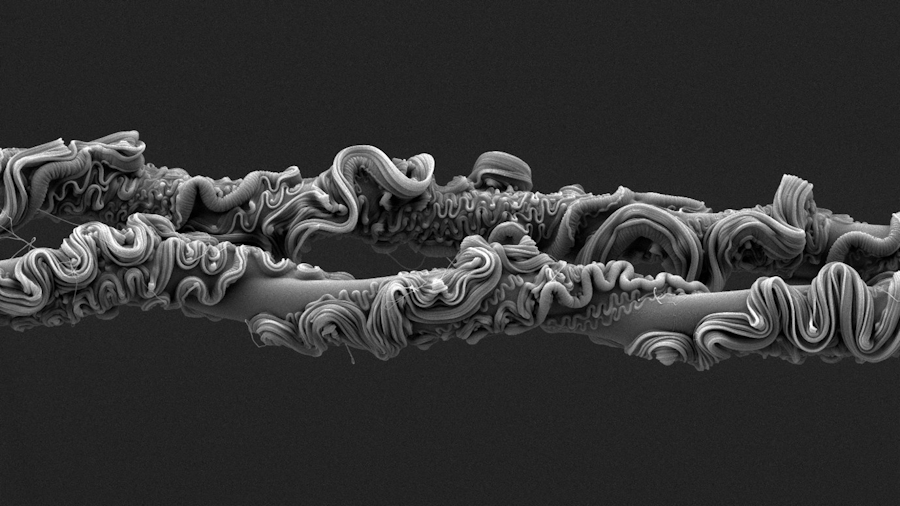

Using high-speed imaging and high-resolution electron microscopy, the research team analysed both the dynamics of how the net is cast as well as the structure of the silk. They discovered a previously unknown structural principle: the central silk threads at the heart of the web-casting spider’s prey-catching net are elastic and by moving its so-called spinnerets – small protrusions in the abdomen – the spider is able to microstructurally adapt its silk by adding windy and crinkled threads to the stretchy ones. This not only changes the metastructure of the silk, but also its material properties. The curly threads are stiffer than the elastic ones and once extended provide added strength to the net.

The differences are particularly clear in comparison to other kinds of silk, for example the external support lines of the web in which the spider lies in wait for its prey. Whilst these have a linear structure with rigid and stable properties, the prey-catching silk has a wool-like, winding structure that is very flexible.

“In order to enable the fast casting of the net, the prey-catching silk is soft and stretchy,” explains Dr. Jonas Wolff from the University of Greifswald’s Zoological Institute. “However, as soon as it has been stretched, these microstructural loops are extended, making the material robust – it turns elastic and rigid at the same time.” Material tests confirm this observation: the curly prey-catching silk was able to withstand extensions of up to 150 percent, whilst the linear, external web silk broke at around 20 percent.

Inspiration for the industry

The discovery of this special silk structure opens up exciting perspectives for materials science. Inspired by the spider strategy, synthetic high-performance fibres could be produced in the future that are flexible and robust at the same time – without having to make the current concessions between stability and elasticity.

Further information

Publication: Wolff, J. O.; Rößler, D.; Joel, A.-C.; Jackel, V.; Büsse, S.; Michalik, P.; Ramírez, M. J.: Behavioral tuning of spider silk thread stiffness circumvents biomaterial trade-offs. Proceedings of the National Academy of Sciences (PNAS). https://doi.org/10.1073/pnas.2529200123.

Contact at the University of Greifswald

Dr. Jonas Wolff

Zoological Institute and Museum

Evolutionary Biomechanics

Soldmannstraße 14, 17489 Greifswald

Tel.: +49 3834 420 4243

j.wolffuni-greifswaldde

@evoimec.bsky.social